Friends, The New England Steam Corporation Board of Directors want to inform everyone that our membership will be changing in 2026.

Usually, NESCo begins its membership drive for the following year in November and December. We will not be doing that anymore. Traditional style memberships will now begin in May and end in May to coincide with Railroaders Day on May 10th.

The reasons for the change are to eliminate conflict with the Holiday Season, and Year End Fundraising Appeals.

Current 2025 members of New England Steam are to be grandfathered, or carried over, up to May 10th 2026. From that date on the new membership will commence.

There will be some other changes as well, such as membership levels, and names. Lifetime Members will not be affected.

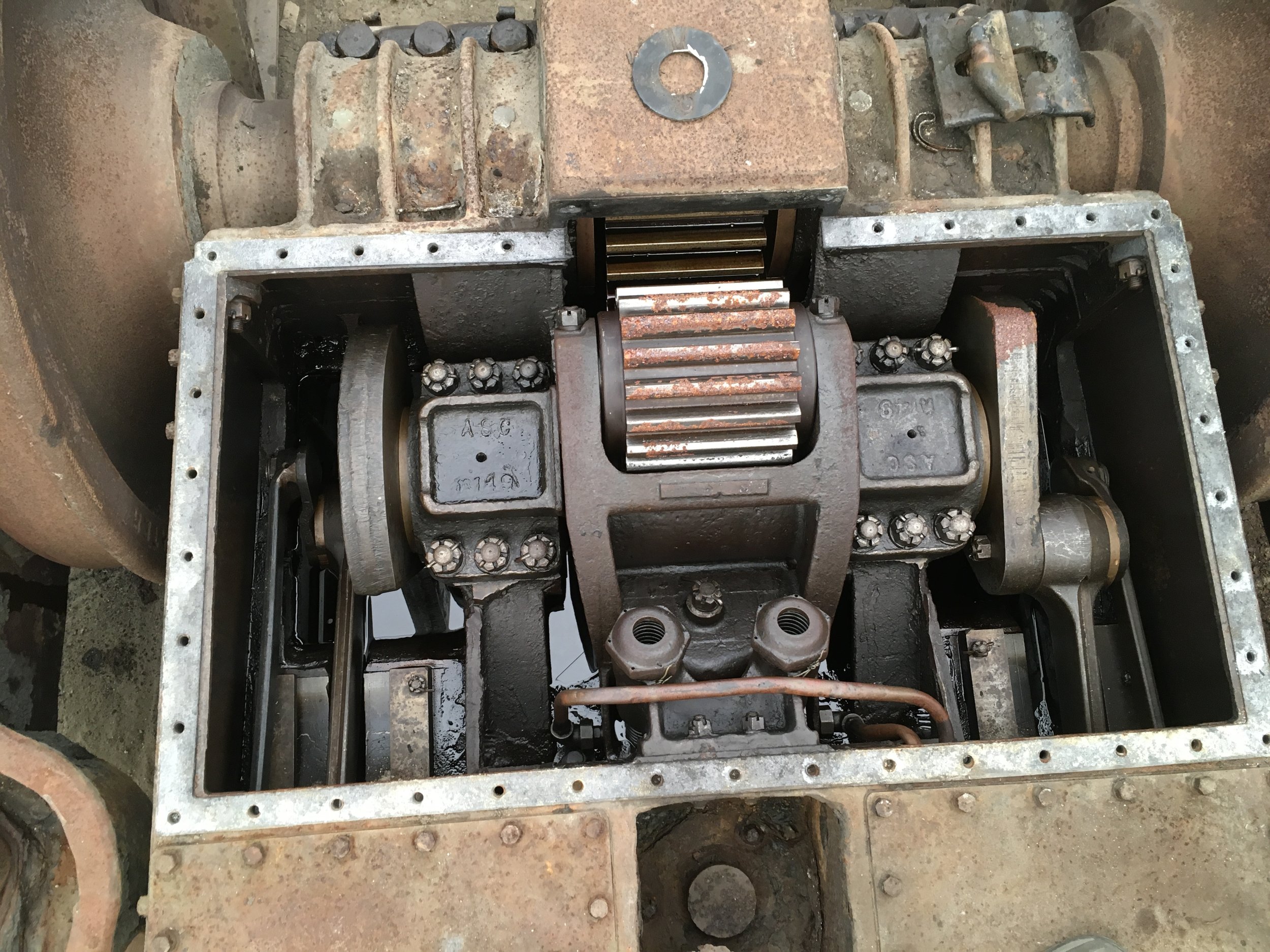

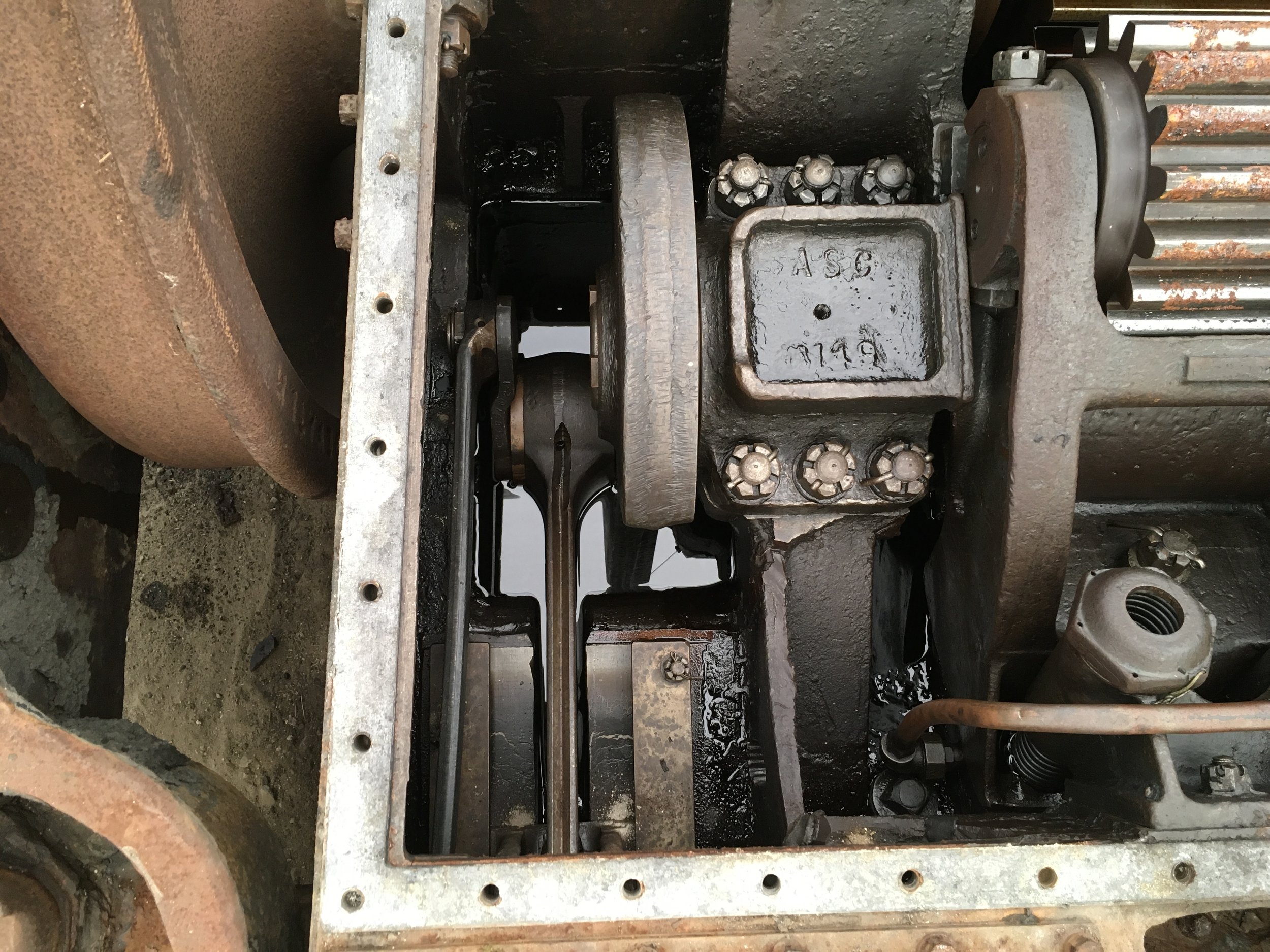

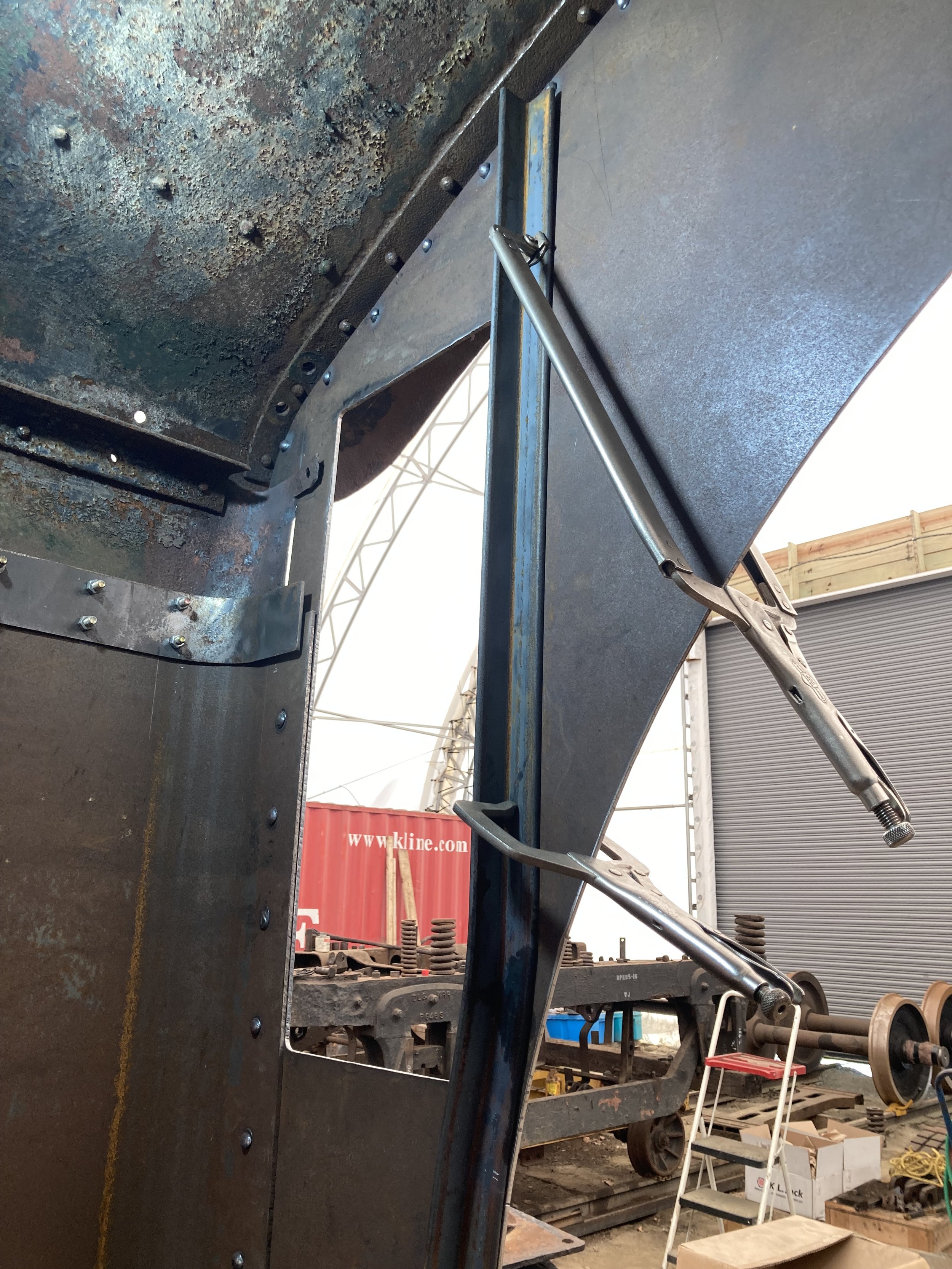

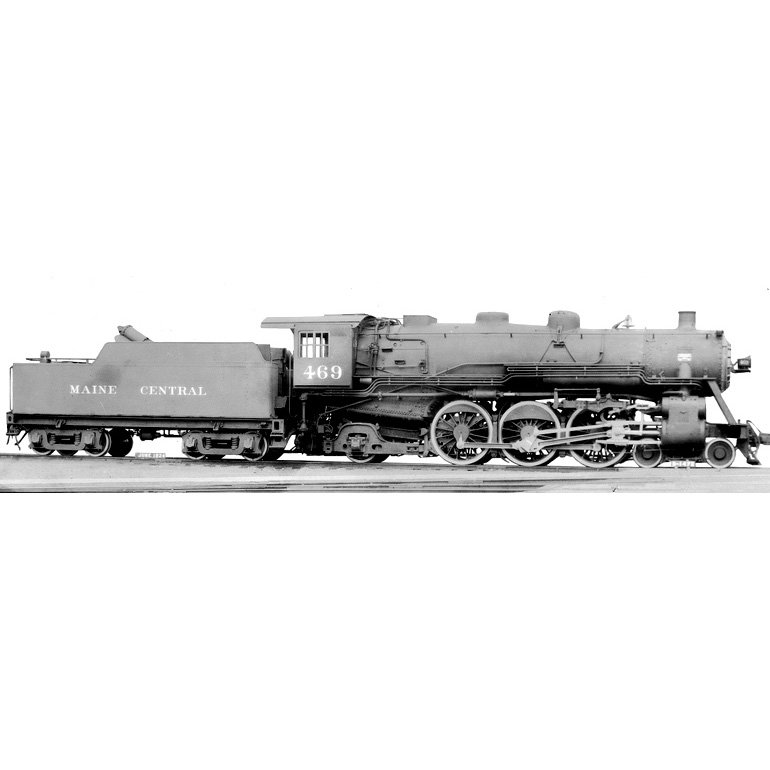

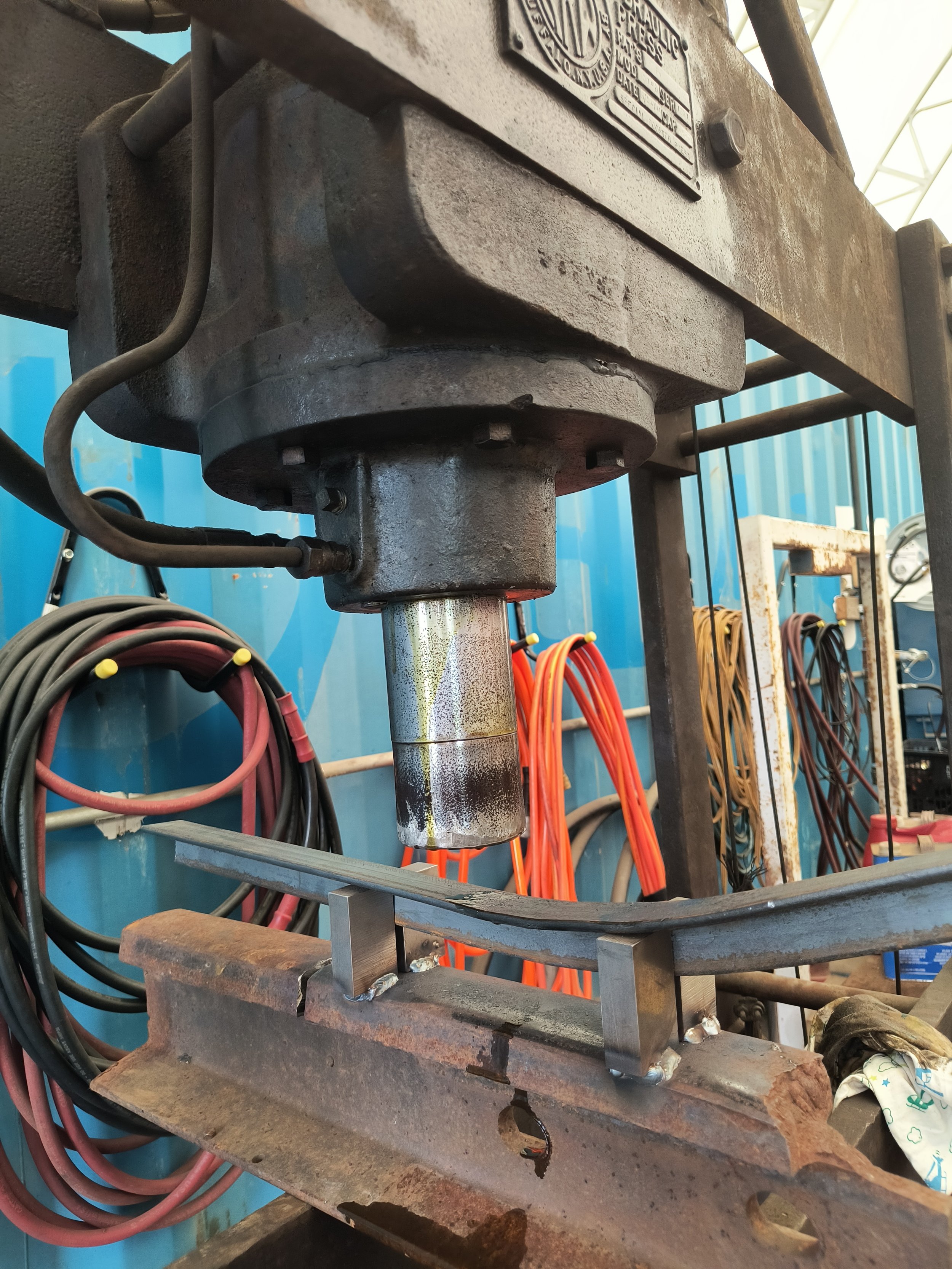

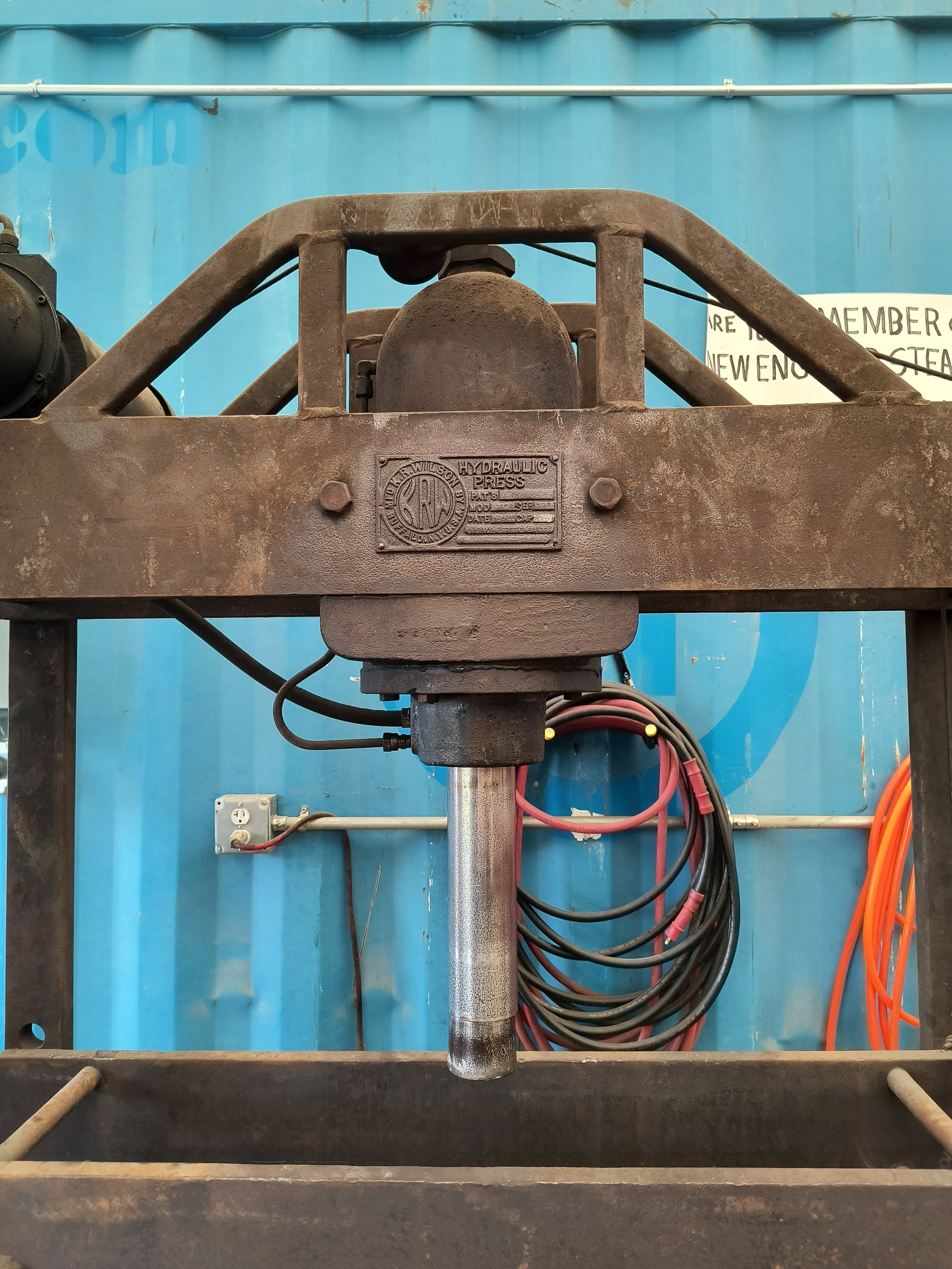

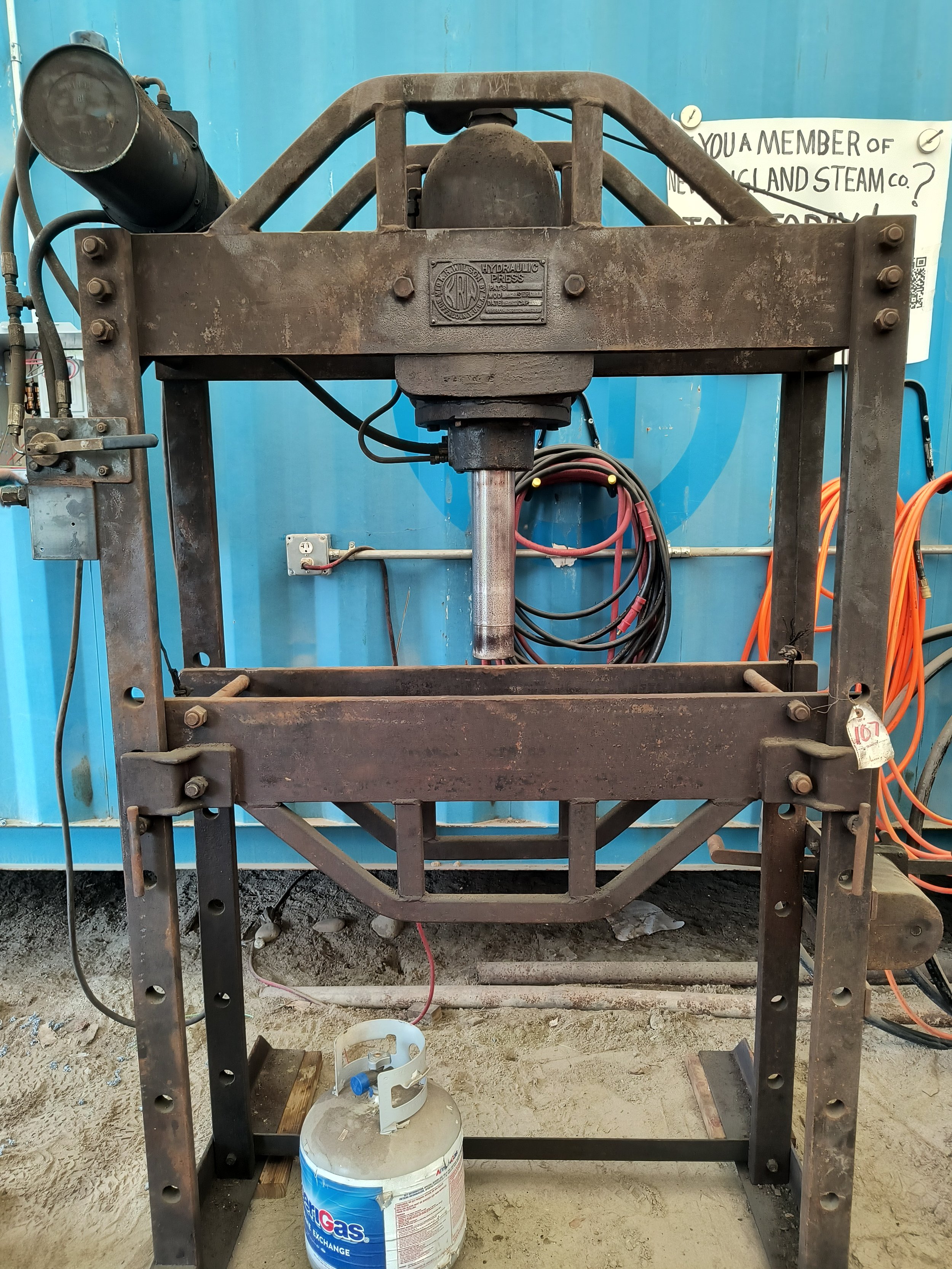

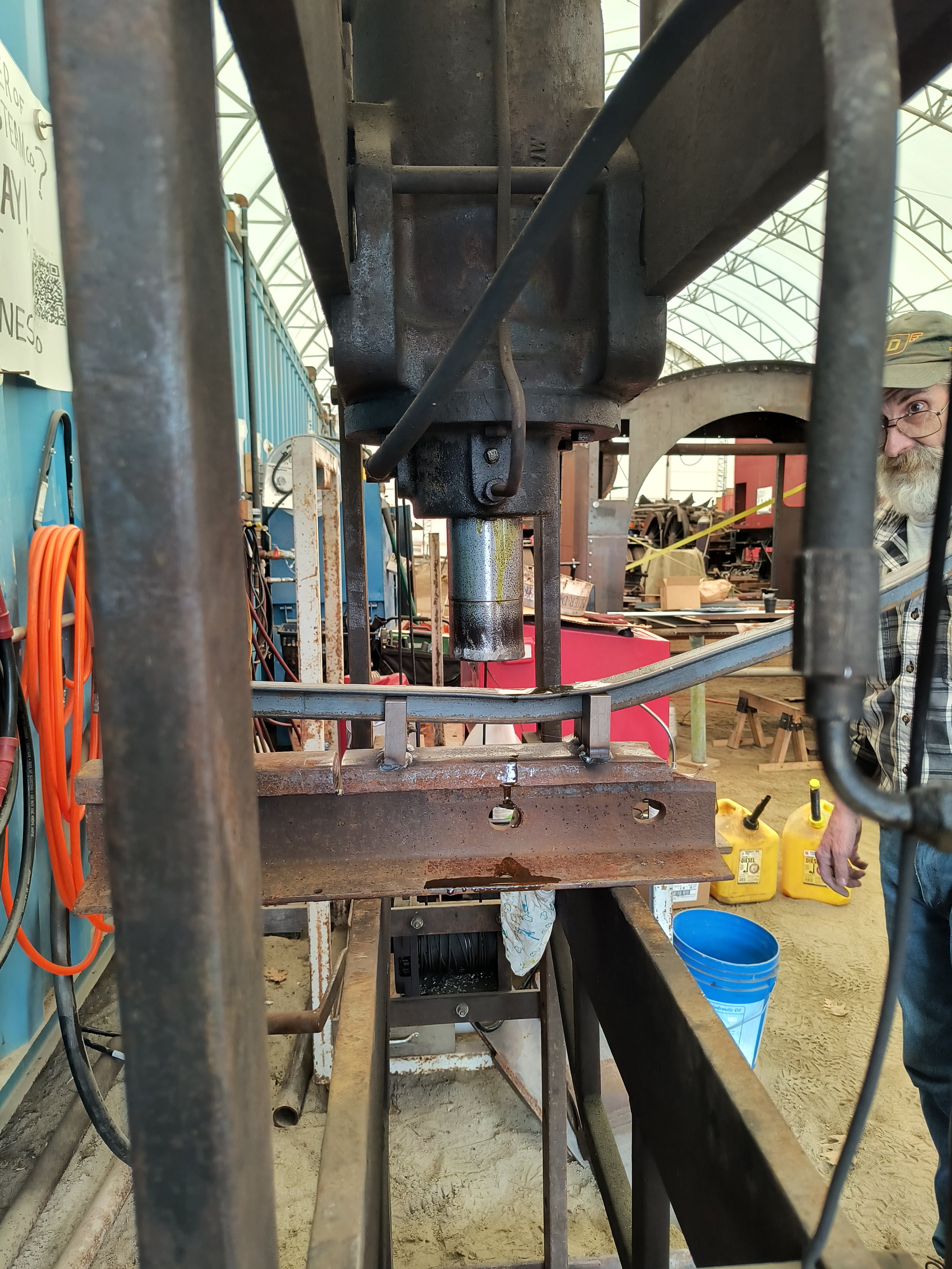

In addition, any person who volunteers to work “Hands On” the 470 locomotive, either in person or in cyberspace will be granted membership status for the remainder of that year. So, plan to save yourself some money by lending a hand with projects on the Old 470!

Stay tuned to this website and our social media pages for more information to be released concerning memberships.