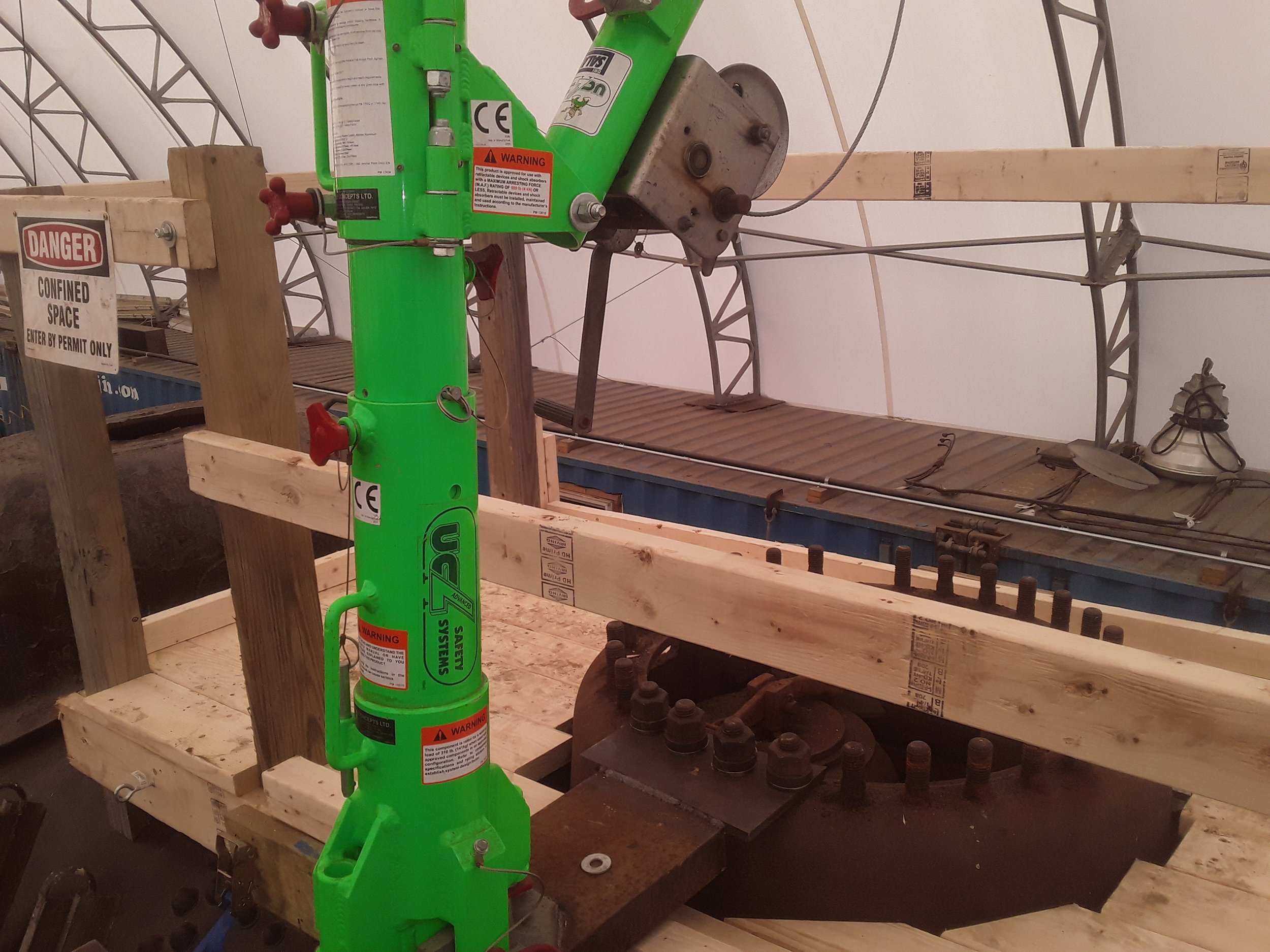

Remember the new air rivet gun that we were trying out? This one?

We gave it a go during the May 27th work session and after setting 2 rivets we had a failure. The shaft snapped…. which is less than ideal.

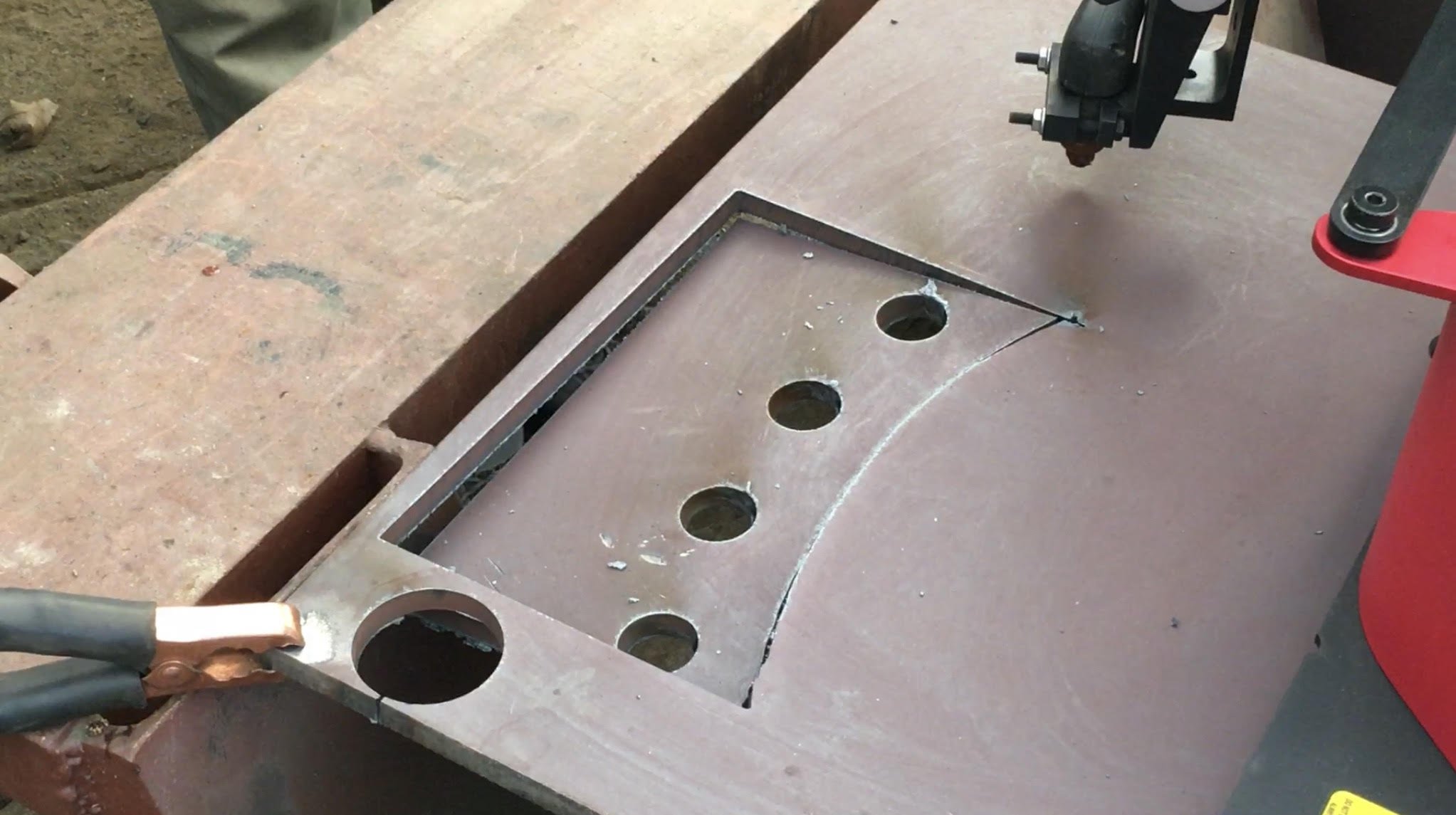

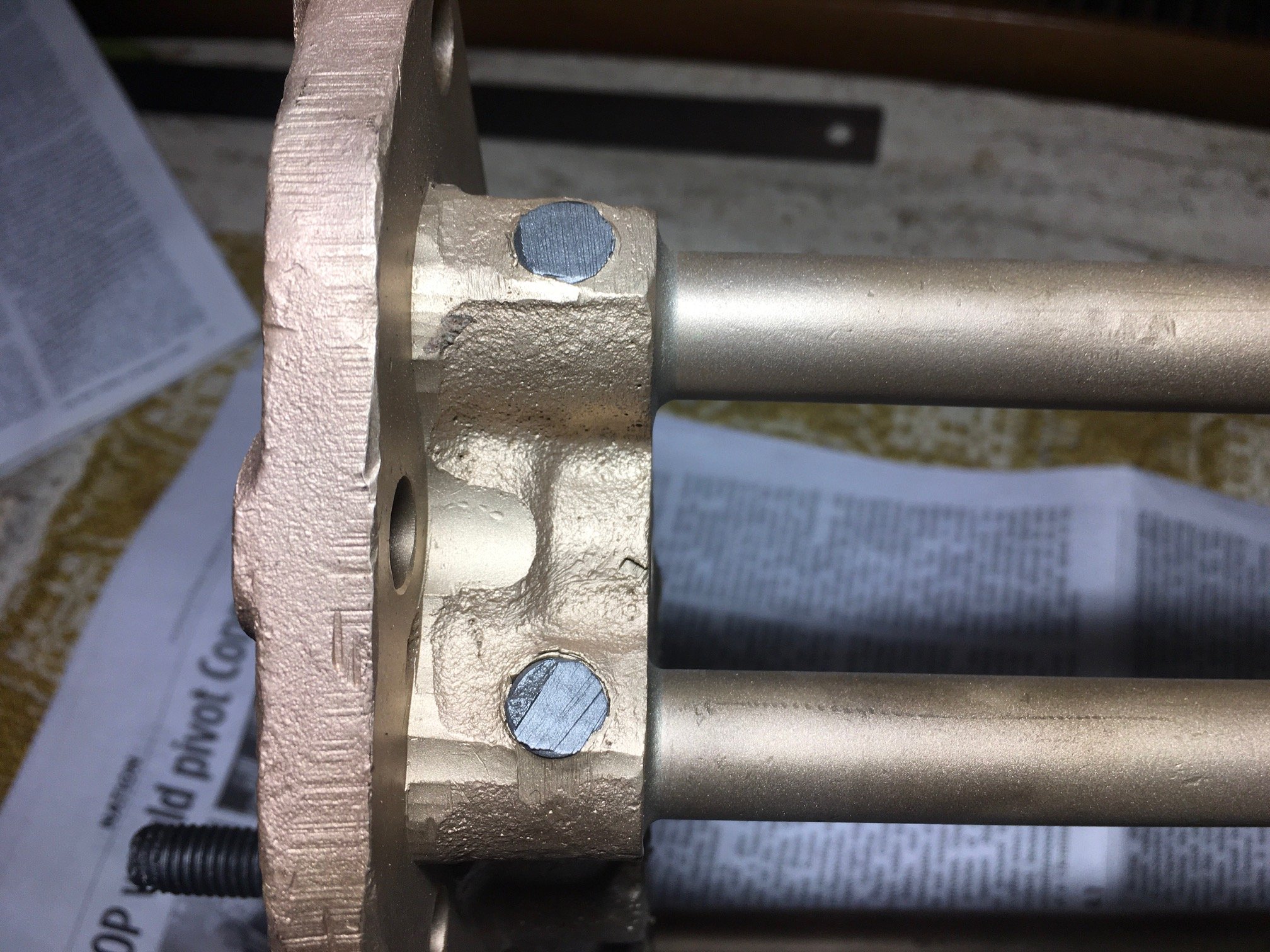

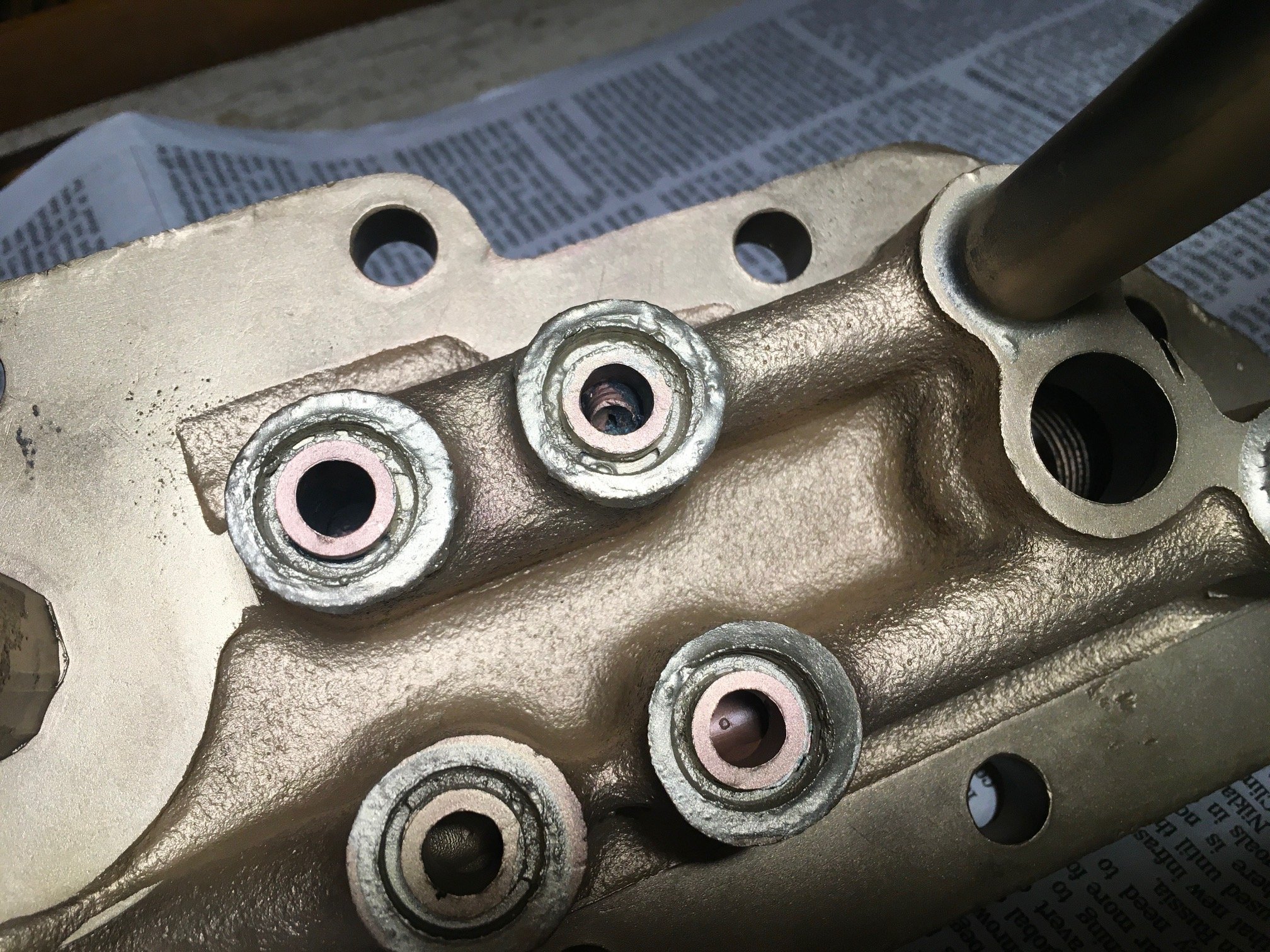

For the next prototype, Bob has converted a chipping hammer mandrel into a rivet setting mandrel to fit the mid-size air hammer we got from Jason. He used an abrasive cut off to lop the pointy bit off and slowly whittled out a female dome to fit our rivet heads for the cab. It was pretty tough metal to work with…..wiped out a hacksaw in a few strokes! In this case, we are hoping that bodes well for its durability. We should be in business now!